Module A3 – Paper and paperboard products

Introduction

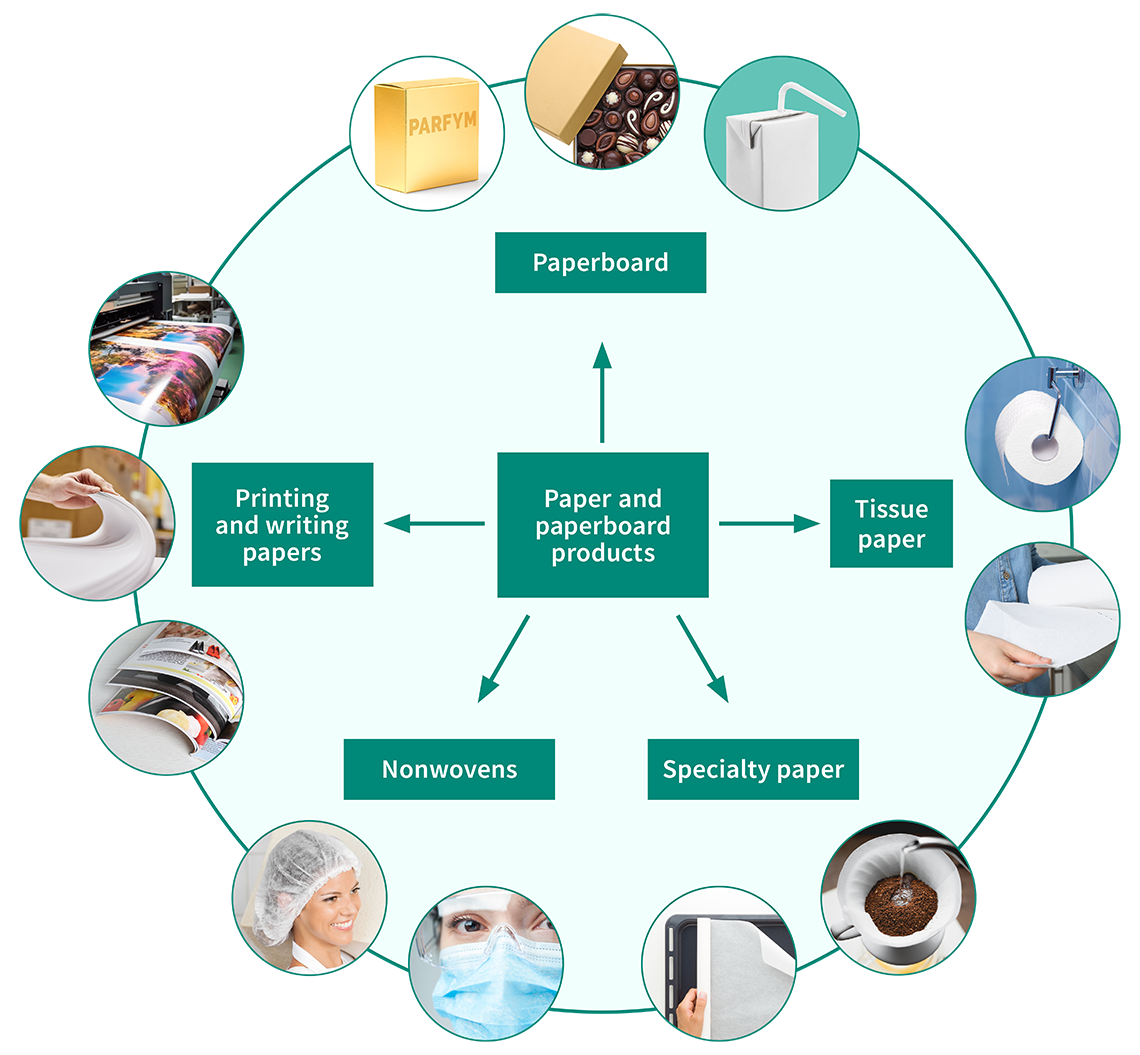

Below you can see images of toilet paper, a kitchen towel, a coffee cup and a magazine. All these products have wood in common as their material of origin. We use many different wood-based products in our daily lives more often than we realise. Many food products are sold in wood-based packaging, we use tissues and hand towels every day and even making your daily morning coffee would be more difficult without filter bags.

In this module, you will learn about paper and paperboard products and study what raw materials are used in manufacturing and what is essential regarding the structure and quality of different product categories.

Pulp

The fibre raw material that is used in production of paper or paperboard is called pulp, which is a slurry of separated wood fibres in water. The process of separating fibres from each other is called pulping, and the fibres can be released either by using mechanical grinding (mechanical pulp), or by chemical cooking (chemical pulp).

Paperboard

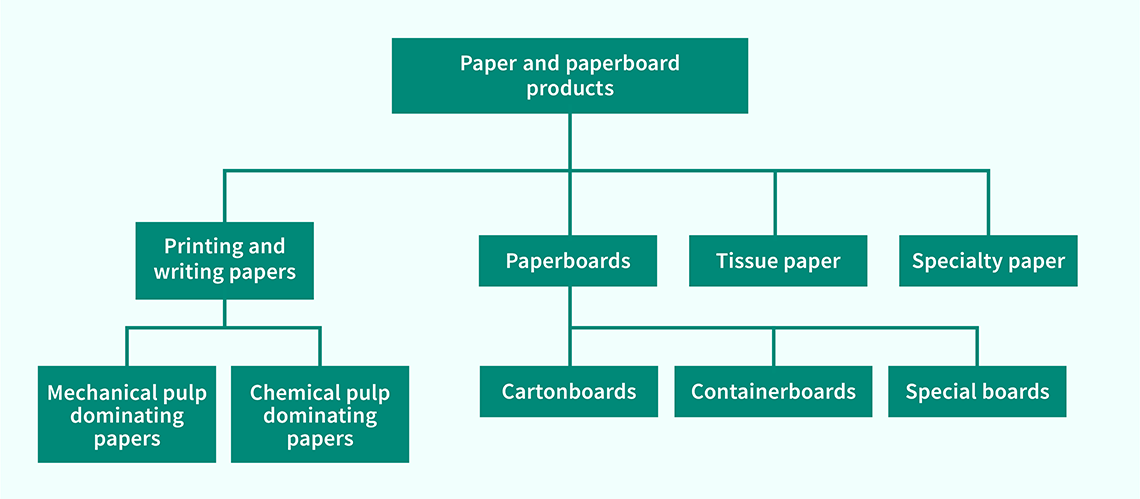

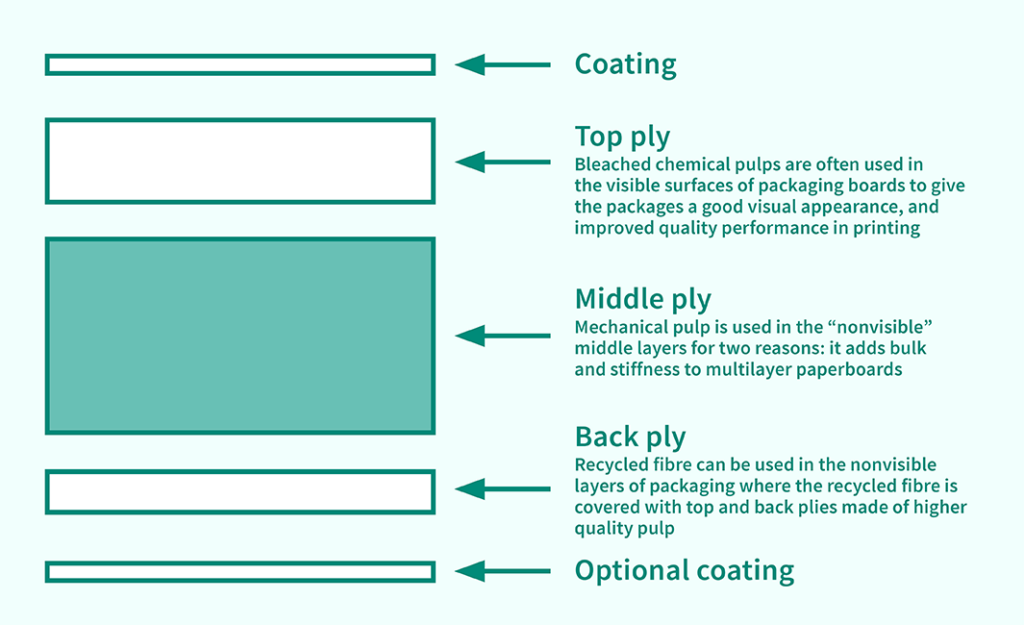

Paper and paperboard products are made from the same raw materials. The main difference between paper and paperboard, aside from the big differences in grammage, is that paper is normally produced as a single layer product, whilst paperboard has multiple fibre layers, plies. Paperboard is classified into three main groups:

- Cartonboard

- Container board

- special boards

Cartonboard

Cartonboards are further divided into separate product categories, such as folding boxboard (FBB), solid bleached board (SBB) and liquid packaging board (LPB) according to the nature of used specific raw materials or specific requirements of their end-use application.

Folding boxboard

If you want to see how folding boxboard is made by Metsä Board, watch the video below.

Solid bleached board (SBB)

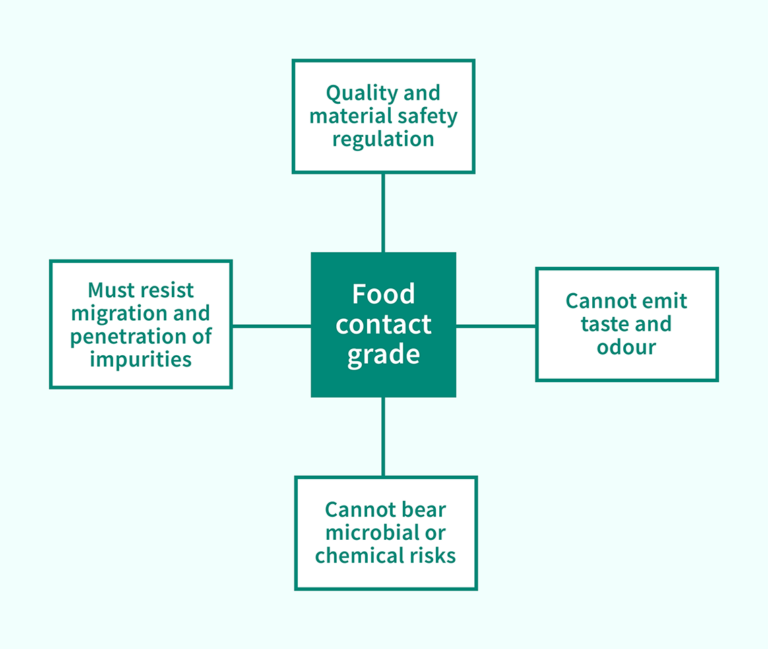

The choice of feasible raw materials for food contact grades is often challenging, and they must be chosen following strictly controlled quality and material safety regulations. Solid bleached board (SBB) is used for various packaging applications. For certain product, like chocolate packaging, SBS is preferred since it does not usually cause problems with odour and taint.

Liquid packaging board

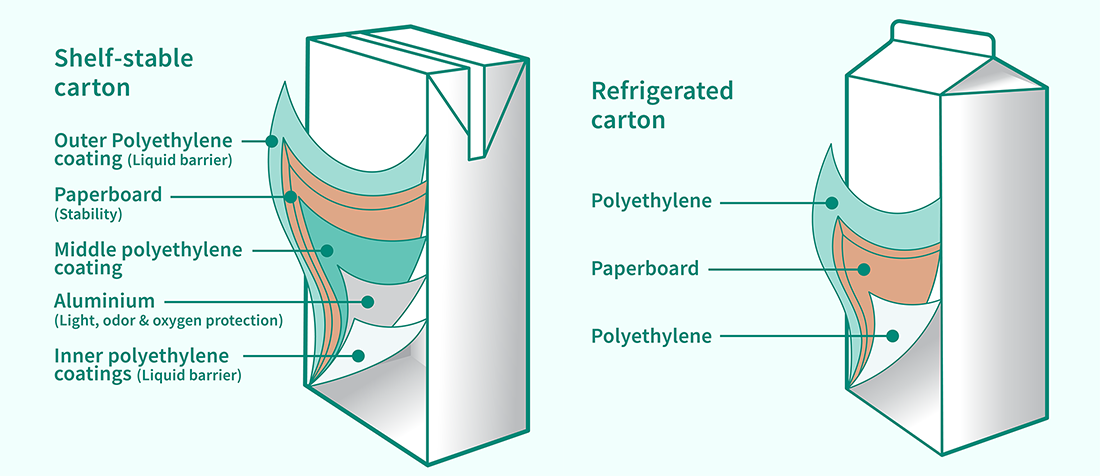

Did you pour milk on your coffee this morning? Did you know that the packaging was made from liquid packaging board (LPB)? There are two types of liquid packages:

- Two-sided low-density polyethylene-coated paperboard for refrigerated carton products, for instance for pasteurized milk products.

- High barrier coated paperboard for long shelf-life liquid products.

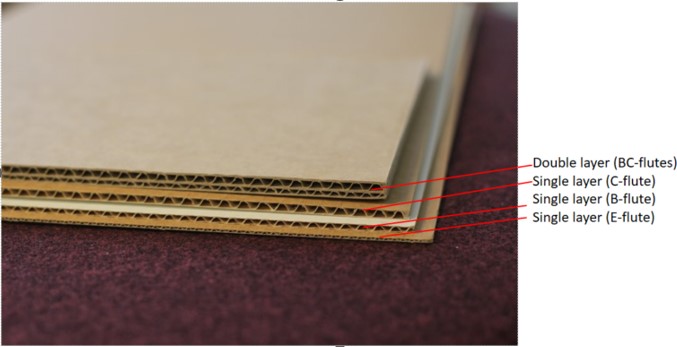

Containerboard

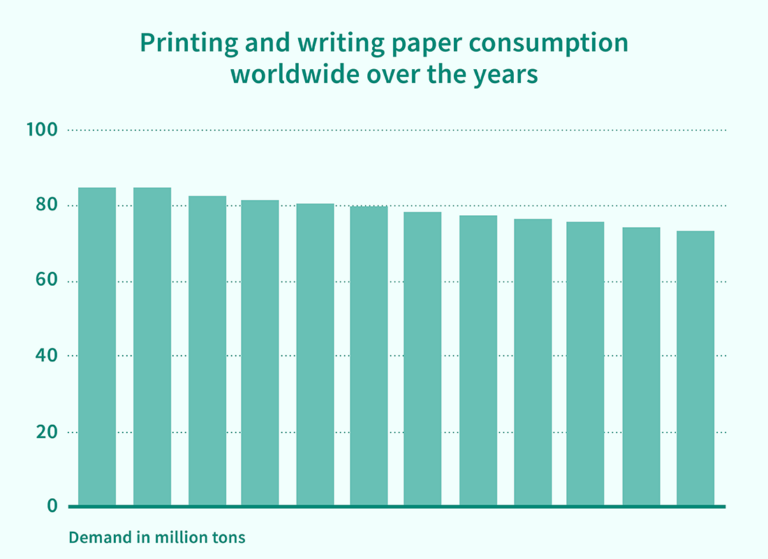

Printing and paper grades

Challenges faced by printing and writing paper industry:

- Increasing electronic media

- Tightening environmental demands

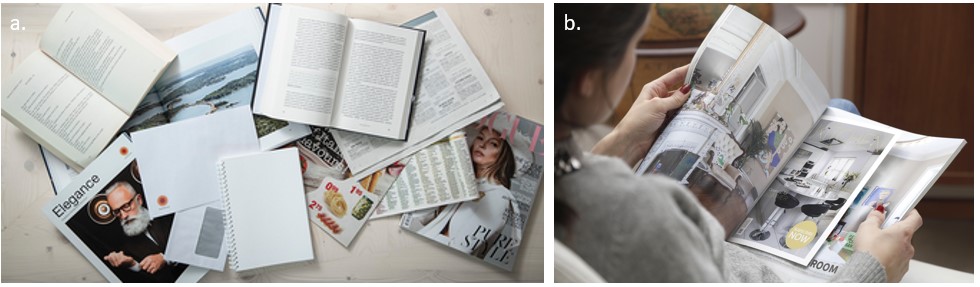

Paper grades are divided based on the pulp used in the production:

- Wood-free papers (chemical pulp)

- Wood-containing papers (mechanical)

- Mixes of both types of pulp

Tissue papers

Tissue papers, for example, paper used for hygienic purposes like toilet paper, serviettes, and kitchen towels, are produced from primary and/or recycled fibre in different blends to generate specific combinations of absorbing capacity, strength, softness and rubbing holdout. Since paper, as such, does not have wet strength properties, several types of chemical additives are used to improve both the wet and dry strength properties of the products.

Nonwovens

The term nonwoven refers to a product category where man-made fibre materials, natural and/or synthetic, are formed into a textile-like web. The fibres are bound together chemically, thermally, or mechanically without weaving and used, for example, in disposable hygienic wear and hazmat suits, protective face masks. Numerous production methods and end-use applications exist for this product category.

Specialty papers

This category of papers includes a multitude of materials with specific functional features. Materials such as baking paper must be grease repellent and heat durable, whilst i.e., coffee filter paper must be wet resistant, heat tolerant, have a well-defined homogenous pore size for even filtration, and be free of heat-dissolving or odour- and taste-emitting materials.

If you want to learn more about specific functional properties of specialty paper, go to Learning path B.

Printing, basics

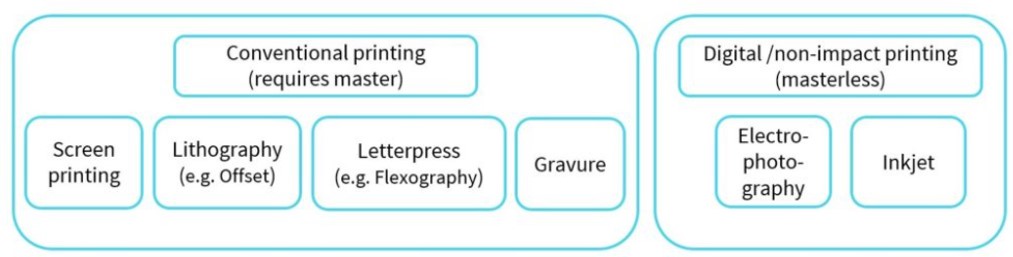

Printing can be done by

- Conventional printing (requires master)

- Digital/non-impact printing (masterless)