Module A1- Safety in forest industry

Introduction

General safety is crucial in any industrial mill. Mills that cover a wide range of operations, from manufacturing and maintenance operations to processing raw materials, require strict and thorough safety procedures to ensure the well-being of workers and to prevent accidents. These general mill safety procedures are also there to maintain a productive environment.

In this module, you will learn about general mill safety procedures that are applicable across all types of mills.

General mill safety procedures

The safety of every mill employee and visitor is ensured by safety standards that are applicable to all. Companies collect safety data from their organisation aiming to understand the root causes of incidents and how to prevent them in the future. Effective risk control measures and rules ensure that everyone stays safe.

Personal Protective Equipment (PPE)

All personnel working in mills must wear appropriate PPE, including helmets, safety goggles, gloves and boots. The PPE requirements might vary based on the work being performed, but their use is crucial and non-negotiable to protect against potential accidents. Note, it is also important to study the mill-specific safety rules.

Machine guarding

In a safe mill environment, the machines are safely protected by different kinds of safety barriers, interlocks, and emergency stops to prevent accidental contact and injury. Do not change or remove the safety equipment without the proper training and permit.

Hazard identification

Companies conduct regular assessments to identify potential hazards within the mill environment. These assessments can help implement preventive measures and reduce the risk of accidents caused by unsafe working environments. Every employee is required to report any risk factors to their employer.

Emergency response

Well-defined emergency procedures should be established, covering scenarios like fires, chemical spills, and medical emergencies. Exit routes, assembly points, and communication methods should be clear and practiced regularly. Remember to observe the nearest exit and other safety procedures.

Chemical safety

If the mill uses of chemicals, strict guidelines for storage, handling and disposal must be in place. Safety Data Sheets (SDS) should be easily accessible, detailing the properties and hazards of each chemical.

Fire safety

Mills often work with materials that can be highly flammable. In a safe mill environment, adequate fire detection systems, fire extinguishers and sprinkler systems are installed and maintained properly. Regular fire drills ensure that employees know how to react quickly and appropriately in case of a fire accident.

Training and education

All mill workers, regardless of their role, should undertake thorough training sessions on safety protocols, emergency procedures and the correct use of equipment. Regular workshops and refresher lessons keep employees informed about the latest safety practices.

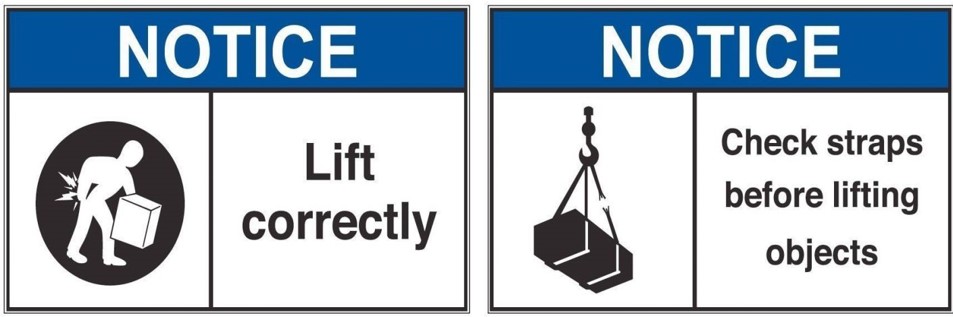

Lifting and handling

Proper techniques for lifting and handling heavy objects should be taught to employees to prevent injuries and accidents. Mechanical assistance (with appropriate training), such as cranes or forklifts should be used when necessary. Never walk under lifted objects or close to moving or rotating machines.

The use of mechanical assistance

The use of mechanical assistance, such as cranes or forklifts, should only be used after having thorough training and the employee must always have a valid work permit with them. Also, employees need to wear a safety belt and must obey the speed limits.

Personal hygiene

In mills where contamination is a concern, maintaining proper personal hygiene, including handwashing and wearing appropriate work clothing, can reduce the risk of cross-contamination. Mills have strict rules not to work under the influence of drugs or alcohol.

Safety culture

Fostering a culture of safety is vital. This involves encouraging employees to report unsafe conditions, near-miss incidents and suggesting improvements to safety protocols without fear of punishment.

A comprehensive approach encompassing training, equipment, hazard management, and a strong safety culture ensures that everyone can work in a safe and secure environment without fear of being injured.